MacGregor Historic Games Rose & Pentagram Design

2229 East 34th Street, Minneapolis, Minnesota 55407

| Ancient lathes | Continual rotation lathes | Spring-pole lathes |

| Bow lathes | Tools | Related Machines |

| Specialty Lathes | Quotes about turning | Notes on a 17th Cent. turner |

| My bow lathe | Bibliography | Links |

Drills & Machines Powered in manners similar to Lathes

There is yet another tool, or rather a Machine used by some Turners called a Drill-Bench. It is described in plate 14. aaaa A thick board about three Inches thick, five inches broad, and eighteen inches long, tow stiles placed towards either end, and fastend upright. In the hindermost stile is a Coller described at 7 and Plate 13 -Joseph Moxon.

A French instrument maker's bow drill

A French instrument maker's bow drillSource: Country Furniture, by Aldren A Watson. Lyons & Burford, publishers.

Button Makers Drills drilling wooden molds for for casting metal buttons.

Button Makers Drills drilling wooden molds for for casting metal buttons.Source: Diderot's "Encyclopedia of Trades and Industry."

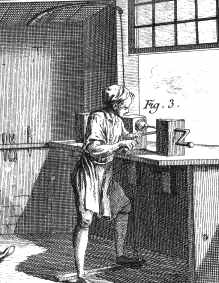

A Button Maker using a spring pole lathe for buffing, or polishing buttons molded of resin.

A Button Maker using a spring pole lathe for buffing, or polishing buttons molded of resin.Source: Diderot's "Encyclopedia of Trades and Industry."

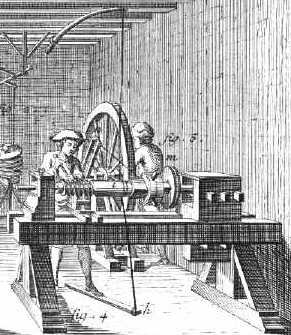

A Toolmakers lathe for cutting large screws.

A Toolmakers lathe for cutting large screws.Source: Diderot's "Encyclopedia of Trades and Industry." See the Screw-cutting lathes on this page Specialty Lathes for a better idea of how this worked.

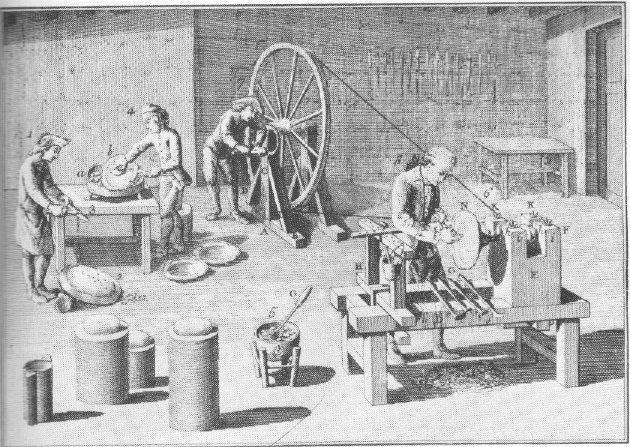

A Cutler's Grinding stone Powered by a great wheel.

A Cutler's Grinding stone Powered by a great wheel.Source: Diderot's "Encyclopedia of Trades and Industry."

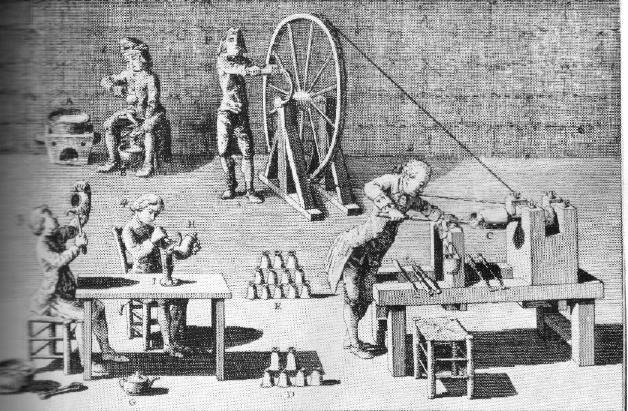

Two Pewtersmith's lathes Pewtersmiths used lathes for polishing their work as well as cleaning off the "flash" from mold lines of their work. They were also used for "spinning" metal. -A sheet of thin metal was held in the lathe and the bent, or formed into the desired shape as it spins. Forming the "cup" portion of a goblet for example. This required a toolrest with upright pegs mounted in it to hold the tool against to provide the required leverage

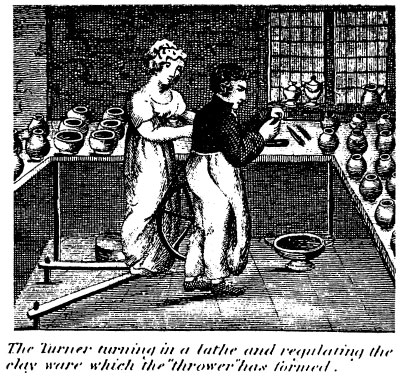

A Potter's Lathe

A Potter's Lathe

I occasionally have heard a lathe compared to a potter's wheel, but this was the first example I have found of a lathe being used for pottery. The woman is supplying the power by pumping the treadle. Apparently in early pottery factories in the late 18th and early 19th centuries it was not uncommon for a male craftsman to have female attendants/ assistants working with them. The clay objects were dried until they were "leather hard" and clamped in the lathe to thin to walls and finish off the design.